Harold Ransburg developed the first electrostatic application system in 1940 with the introduction of the Ransburg No1. Further developments through the 50s and 60s lead to Ransburg achieving material transfer efficiency levels of up to 98% with significant reductions in overspray, resulting in dramatic cost savings and reduced VOC emissions. Today Ransburg's cutting edge technology has led to the development of rotary atomisers such bell and disc applicators.

- Home Page

- Devilbiss Spray Equipment

- Wagner Spray Equipment

- Hasco Spray Equipment

- Pressure tanks

- King Lifting Equipment

- Air Tools

- Contact Us

- POPI Compliant

Ransburg RansFlex Electrostatic Manual Spray Gun

Overview:

Ergonomic fit, feel, balance and controls

Operators experience less stress on joints and muscles which has proven to lower the risk of RSi and the impact of physical strain, reducing operator fatigue.

Redesigned sleek and smooth exterior

Makes cleaning and maintenance fast and easy whilst protecting key components.

Triple Turbine Protection

Three phases of turbine protection include a divorced turbine air supply cartridge, sealed nozzle/atomisation passages and the strategic turbine location provide a long trouble free working life.

Ergonomic handle profile and comfortable trigger

Contoured palm engagement which reduces the grip force to hold the gun over long periods.

Meets ATEX-CE/FM/CSA

Complies with all globally recognised safety standards.

Easier to maintain

With 20% fewer parts than previous models, RansFlex is easier to maintain and the patented turbine utilises a three-phase motor to reduce vibration and provide electrostatic power at lower input air pressures. RansFlex features quick voltage on/off controls on the gun with quick detach air hose connector at the handle to further reduce weight. Indexing air caps with unique colour coded fluid tips for easy identification, make RansFlex the perfect Electrostatic solution for all finishing applications.

Cordless portability and convenience

No generators or controllers Superior atomisation and transfer efficiency Lighter weight with superior ergonomic balance Quick and easy to set up „straight from the box“ Lower running costs and maintenance For most solvent based paints and materials.

Best in class atomisation in a compact, lightweight applicator, the all new RansFlex spray gun provides new features and benefits that surpass all other electrostatic applicators. RansFlex is a low pressure air atomising electrostatic spraygun powered by an inbuilt turbine. Designed with the operator in mind, the handle incorporates many fit and feel improvements with better balanced weight to reduce operator fatigue. DeVilbiss World renowned air cap atomisation technology is coupled with Ransburg electrostatic power to provide superior atomization, transfer efficiency and performance, all backed by a 5-year limited warranty.

Ransburg Vector Low Pressure Electrostatic Spray Gun Range

VECTOR the electrostatic spray gun range from the World leaders in electrostatic innovation.

Ransburg Vector, the new generation of manual electrostatic sprayguns for all low pressure application. Reduced weight and trigger-pull combined with an improved ergonomic design make the Ransburg Vector Range the most sought after manual electrostatic gun range in the world.

- Superior atomisation and transfer efficiency

- Lighter weight with improved operator ergonomics

- Increased durability and reduced maintenance

- Redesigned electrostatic controllers - provide quick and simple operation

- Easy to clean and maintain

VECTOR the new electrostatic spray gun range from the World leaders in electrostatic innovation.

RANSBURG engineers have reinvented the electrostatic spray gun by significantly improving paint atomisation, transfer efficiency, durability and operator comfort with greatly simplified controls. That’s the new Vector - Improved from grip to tip!

VECTOR is the cost-effective solution for all low pressure electrostatic painting processes with complete compliance with European Environmental Legislation. VECTOR provides considerable advantages compared to any other.

Improved ergonomics

The incredible reduction in weight has been achieved thanks not only to the light weight, stronger and more durable polymers used to manufacture VECTOR electrostatic spray guns, but also and by the redesign of the high-voltage cascade generator. The shifting of the centre of gravity, a slender, highly

manoeuvrable design and soft trigger with adjustable finger grip ensure utmost user comfort.

The trigger pull force of VECTOR spray guns has been reduced by 50% and the dual stage air valve eliminates air to fluid transition.

Optimised atomisation and coating efficiency.

The new Vector design redistributes the pressure in the air cap adjusting the balance between the atomization and fan air. This causes paint particles to move slower through the charging field which allows stronger charging and more paint delivered to the part with less overspray.

VECTOR spray guns are equipped with pretested certified air caps, designed to deliver consistency,

with the best quality atomisation. VECTOR is also fitted with a precision indexing fan air control valve for easy operation by both left and right hand operators.

Improved Durability

VECTOR spray guns have 25% fewer components than other electrostatic spray guns. The design of the thread on the gun barrel is coarser for easy air cap and fluid tip removal while reducing the chance of cross-threading. All O-rings and seals are manufactured from Kalrez, a highly resistant material that extends Vectors lifespan.

VECTOR cascade spray guns incorporate ‘triple set point’ push button control putting unparalled voltage control right at the users finger tips. This push button turns the voltage on and off and can also move between three 'pre set' voltage levels.

Improved electronic control Vectors control unit offers the operator ’triple set point’ voltage control, plus power on and off, right on the cascade spray gun. This microprocessor based control allows for data to be collected. This data can then be used to correlate the amount of paint used and parts painted.

The illuminated LED display on the control unit is visible at distances up to 15 metres. External controls can be connected via the integrated connection terminals.

Optional multi-position mounting brackets are available

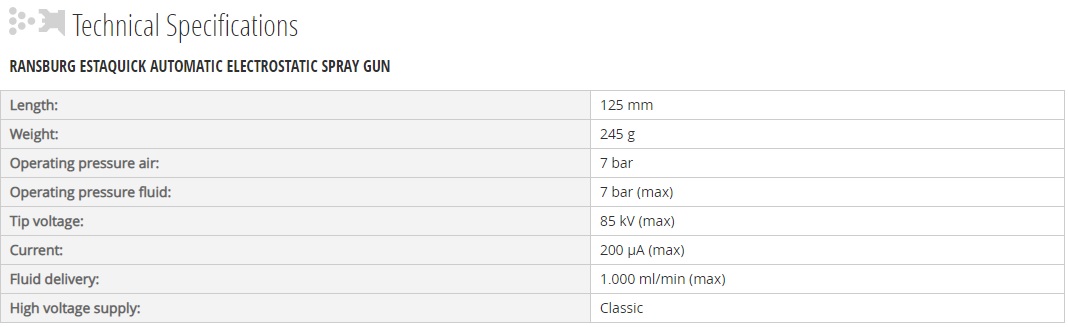

Ransburg Estaquick Automatic Electrostatic Spray Gun

Overview

Gun fits Automatic/Traversing machines

High output paint flow capability (up to 1000cc/minute)

Single OR twin pack (2K) material compatibility independent control of Atomising air, Fan air and Operating air

Guaranteed spray repeatability - Estaquick Air Caps are accurately located onto the Gun Head to provide consistent spray repeatability

Quick disconnect fluid tip (1/4 turn bayonet type).

The Estaquick is a quick disconnect electrostatic air atomising spray gun, which delivers optimum atomization quality coupled with the efficiency of electrostatic performance. The spray head is manufactured in Peek material to make it robust and compatible for most paint materials. The gun disconnects for service in less than 5 seconds thanks to an easy 90° turn mounting bracket.